Are synthetic diamonds real? The short answer is yes. Companies have even made them from salad dressing. Find out the science behind how lab-created diamonds are made and what they are worth.

From Salad Dressing to Diamond

Salad dressing is remarkably versatile. Not only does it dress up salads, but it also doubles as marinade, dip, pasta sauce, or spread — even as a feedstock material for creating diamonds.

As an example of the latter, California’s Hidden Valley recently sent a few bottles of its popular, nationally marketed ranch dressing to a commercial diamond-synthesizing lab. The lab charred the creamy dressing, then converted the residue into the graphite form of carbon. After being subjected to a temperature of 2,500°F and a pressure of 400 tons per square inch, what had been salad dressing days earlier emerged as a synthetic diamond. After faceting, the glittering 2.01-carat, round brilliant gem sold at auction for $12,500.

Hidden Valley basked in a wave of publicity, even though the transformation of its salad dressing into a gem diamond was, from the scientific standpoint, nothing unusual.

Gem-quality diamonds have previously been synthesized from many carbon-rich materials, including peanut butter, motor oil, and even the cremation ashes of pets and family members.

From Alchemy to Science

Hidden Valley’s so-called “ranch-dressing diamond” is just the latest chapter in the long history of diamond synthesis. Medieval alchemists, intrigued by the beauty, rarity, exceptional hardness, and great value of diamonds believed that they consisted of magical material. They attempted to make diamonds by transmuting such materials as glass, quartz, and even ice.

Scientific efforts at synthesis began after 1797 when British chemist Smithson Tennant burned diamonds in oxygen to produce carbon dioxide, proving that diamonds consisted not of anything mystical, but simply of the element carbon.

New Diamond Technology

Are Synthetic Diamonds Real – Making Diamonds

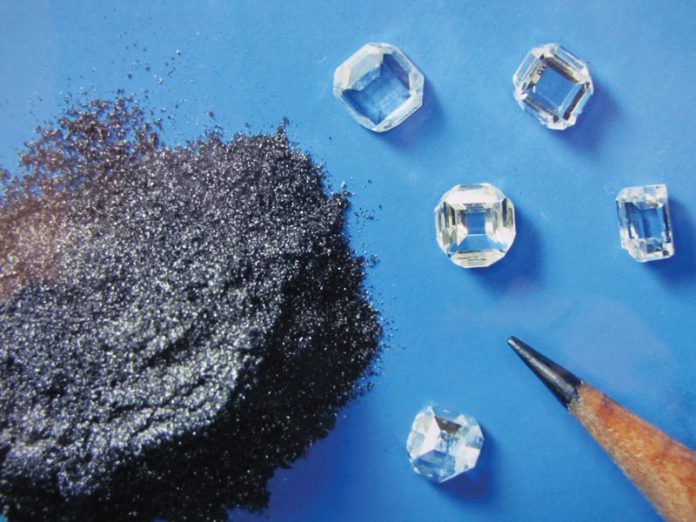

By the mid-1800s, researchers theorized correctly that the flat, hexagonal arrangement of graphite’s carbon atoms, if subjected to enough heat and pressure, could be forced into the cubic configuration of a diamond. Would-be diamond-makers — both serious researchers and get-rich-quick entrepreneurs — embarked on a succession of experiments that ranged from the scientifically logical to the woefully misguided.

At first, hopeful diamond makers used only high-pressure, high-temperature (HPHT) methods. But by the 1940s, scientists had also learned that the catalyzed breakdown of acetylene and other simple hydrocarbon gases at ambient temperatures and low pressures caused carbon atoms to condense as microscopic diamond particles, a process known as chemical vapor deposition (CVD).

Syntechno Ltd.

The Breakthroughs

In 1952, researchers used CVD in the first documented case of diamond synthesis.

But because CVD initially produced only microscopically thin, polycrystalline layers rather than single, cuttable macrocrystals, the process received little public attention.

The following year, Swedish HPHT researchers succeeded in creating small, individual diamond crystals but kept their success a secret in hopes of being able to synthesize larger, gem-quality diamonds before disclosing their process.

Diamond synthesis finally made headlines in 1954, thanks to work conducted at the General Electric Research Laboratory in Schenectady, New York. Using the HPHT process and an enormous hydraulic press that generated 500 tons of pressure per square inch, GE researchers produced diamond macrocrystals. The announcement of this achievement made international news. It also caused the price of natural diamonds to plummet until GE repeatedly emphasized that its tiny, opaque synthetic diamonds were only industrial-grade and not gem-quality.

General Electric

Gem-Diamond Synthesis

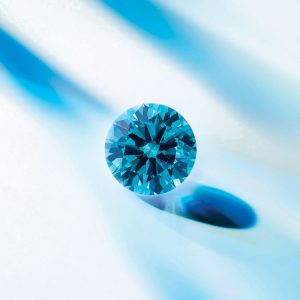

In 1971, GE produced the first HPHT, gem-quality, synthetic diamonds that were large enough to cut. The process, however, was not commercialized because production costs substantially exceeded the cost of mining natural diamonds. Over the following decades, synthesizing costs decreased steadily and researchers learned to make larger diamonds and even color them with chromophores such as nitrogen and boron.

Today, hundreds of commercial laboratories around the world create synthetic diamonds using both HPHT and CVD processes. Annual production of industrial-grade, synthetic diamonds for abrasive and cutting uses now tops 4.6 billion carats (roughly 3,000 tons) and accounts for 95 percent of the industrial diamond market.

About 100 tons (ww450 million carats) of gem-quality diamonds are now being produced annually. Synthetic diamonds account for nearly seven percent of the global diamond jewelry market. Their appeal is greatest among younger consumers who favor synthetic diamonds over mined diamonds for environmental and humanitarian reasons. But the biggest marketing advantage is, of course, affordability. Synthetic gem diamonds, which are visually indistinguishable from their natural counterparts, now cost as much as 75 percent less than comparable natural stones.

Somewhat surprisingly, synthetic gem-diamond demand is being driven not by jewelry use, but by high-tech industrial applications.

Diamond’s extraordinary heat-conducting properties make it an ideal heat-sink material to absorb and dissipate excess heat in electronic microchips.

The Future of Synthetics

Just how far gem-diamond-synthesis technology has progressed is uncertain. The field is very competitive and the many commercial variations of the HPHT and CVD processes are closely guarded, proprietary secrets.

Synthesizing technology is rapidly advancing not only in lower production costs but also in the increasing size of synthetic gem diamonds. Just recently, two faceted, 10-carat, synthetic diamond gems, one colorless, the other deep blue, sold for $420,000. The largest synthetic gem diamond produced thus far weighed more than 30 carats. Diamond synthesizers are confident that rough stones of 40 and perhaps even 50 carats are just around the corner.

The increasingly routine nature of making diamonds has prompted a standing joke among diamond synthesizers. Pointing out that it is no longer any great feat to make diamonds from materials like salad dressing, they wryly note that a much greater technical challenge would be to make salad dressing from diamonds.

This story about are synthetic diamonds real appeared in Rock & Gem magazine. Click here to subscribe. Story by Steve Voynick.