By Bob Rush

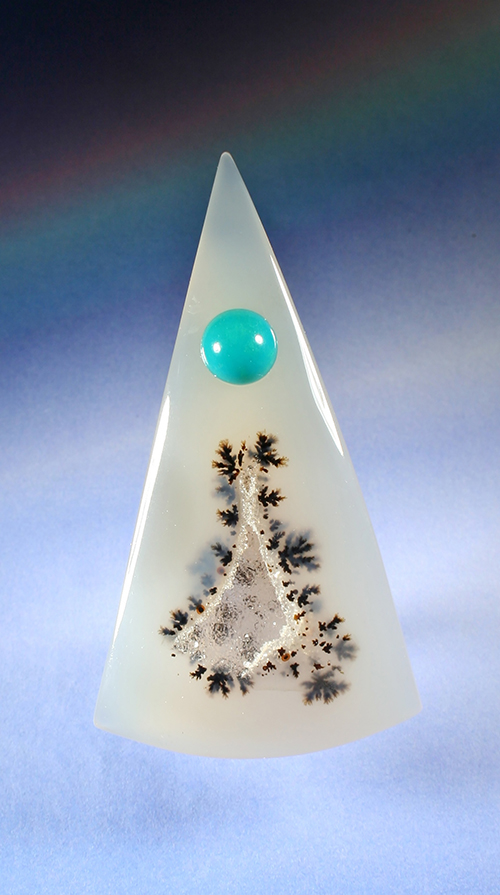

Recently, when I was slabbing a large Brazilian agate nodule, looking for some milky chalcedony within it, I chanced upon a druzy cavity surrounded by small dendrites. Fortunately, the cut was at just the right place for me to make a striking cab from the pattern. This piece has an opening where the druzy background is well exposed.

The shape of the rough slab allowed me to form the cab into a triangle. After shaping the cab, I had an inspiration to mount something between the top of the dendrites and the tip of the cab. I haven’t done much inlay into the front of a cab, so this was a great opportunity to learn how.

Task by Task

My first task was to decide what shape, size and material would look good with the overall shape and material of the cab. Due to the limitation of my skills and experience, I decided a round shape would give me the best chance of success.

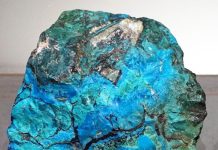

I thought about using carnelian, lapis, chrysoprase or—my preference—gem silica. I couldn’t find any gem silica in my pile of rocks, so I chose chrysocolla. I decided that an 8 mm, round stone would fit the best. I trimmed the rough and ground it to shape. I then dopped it and finished doming the cab with my small sphere cup, mounted on my flat lap machine.

After shaping the small cab, I polished it in preparation for mounting. I took careful measurements on the larger cab to ensure the smaller one would be centered correctly. I started the hole with a 2 mm round diamond bur. Next, I used a round 220 diamond bur that was slightly smaller than the chrysocolla cab to make the hole for mounting it. Because the hole had a round bottom, it would need to be reshaped to form a seat for the cab. I used an inverted cone diamond bur so I didn’t inadvertently enlarge the hole as I made the stone seat.

Get the scoop about the latest rock, gem, and mineral features and news, rock shop and rockhound profiles, and exclusive freebies and promotions in your inbox. >>>

Fitting A Cab Into Its Mounting

Fitting the small cab into its mounting took special care so that no gaps were left between the stones. For this step, I used a 400 grit diamond cylinder bur. The upper edge of the hole had a tendency to chip, especially if the bur was too coarse or I applied too much pressure to it. Slowly, I ground the hole larger, and checked the fit many times. Once it fit down into the hole, I checked the depth of the seat to make sure that the small cab was at the right height. Even with care, the upper edge of the hole, as expected, had some small chips.

I had allowed for this when I originally shaped the larger cab so it was just a matter of re-sanding over the hole to remove the chips. The final step was to mount the small cab with epoxy 330.

A professional within the lapidary industry since 1958 and metal work and jewelry since 1972.

A professional within the lapidary industry since 1958 and metal work and jewelry since 1972.