By Bob Rush

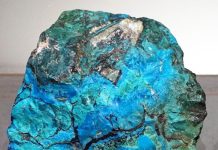

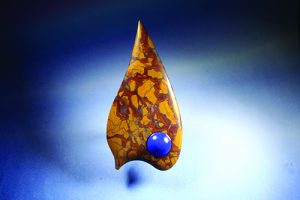

Would you like to mount a small accent cab within a larger cab? It is easier than you might think! To illustrate, I chose a piece of Stone Canyon jasper as the base cab. Striking red patterns surround tan brecciated areas, and the red would contrast nicely with blue, so for an accent cab I chose lapis.

I sketched a pattern for the base cab on the surface of a Stone Canyon slab with an ink pen, choosing a free-form design with tight inward curves. The accent cab would be offset toward the bottom of this base cab. I used standard cabbing steps except for working the inward curves, which I ground with 1-in. mizzy wheels run dry followed by sanding on my 8-in. expando wheels using silicon carbide belts.

Working with a Wooden Dowel

I slid the belt off the edge about [3/8]-inch and worked the cab over the edge of the wheel to sand the inward curves. I then used a half-inch wooden dowel wheel mounted in a flex shaft handpiece to polish inside the curves. I finished the cab all the way through the polishing stage prior to beginning the steps to insert the accent cab.

I slid the belt off the edge about [3/8]-inch and worked the cab over the edge of the wheel to sand the inward curves. I then used a half-inch wooden dowel wheel mounted in a flex shaft handpiece to polish inside the curves. I finished the cab all the way through the polishing stage prior to beginning the steps to insert the accent cab.

I fabricated the lapis cab using my regular cabochon machine to preform it and my small sphere cup on my modified flat lap machine to make the dome. I left a flat 1.5 mm girdle on the cab.

I marked the location for this accent cab with a circle template on the jasper cab and located the center of the circle. I started grinding the mounting hole with a small round diamond bur. These will drill much faster by using the side of the bur. If you push vertically, the grinding action is slower because the very center of the bur isn’t doing much work.

Get the scoop about the latest rock, gem, and mineral features and news, rock shop and rockhound profiles, and exclusive freebies and promotions in your inbox. >>>

Use of Diamond Bur

After drilling about halfway through the cab, I switched to a larger diamond bur, about 2 mm smaller than the accent cab. You don’t want to end up with the hole larger than the cab. Again, use the side of the bur, but be careful because it will want to dig in on the leading side, and you will end up with an oblong hole. Rotate the larger cab around so the hole remains perfectly round. Drill this hole down halfway through the cab.

I established the seat for the accent cab using an inverted cone diamond bur. Hold the  jasper cab firmly and—using the bottom and side of the bur—grind the seat, keeping it level with the top of the hole. The depth of this seat should match the 1.5 mm flat girdle on the accent cab. The final sizing of the hole is done with a cylinder bur with a flat bottom that has no diamonds. Slowly and evenly enlarge the hole to fit the accent cab. Check the diameter of the hole frequently with a machinist’s caliper while also trying the fit of the accent cab itself.

jasper cab firmly and—using the bottom and side of the bur—grind the seat, keeping it level with the top of the hole. The depth of this seat should match the 1.5 mm flat girdle on the accent cab. The final sizing of the hole is done with a cylinder bur with a flat bottom that has no diamonds. Slowly and evenly enlarge the hole to fit the accent cab. Check the diameter of the hole frequently with a machinist’s caliper while also trying the fit of the accent cab itself.

When the cab just fits, you are ready to finish. Sand and polish over the top of the hole to eliminate the inevitable chips on the edges. When this is done, the accent cab can be mounted with epoxy 330, and the fit on the finished cab should be excellent!

A professional within the lapidary industry since 1958 and metal work and jewelry since 1972.

A professional within the lapidary industry since 1958 and metal work and jewelry since 1972.