By Steve Voynick

By the late 1950s, exploration geologists in the western United States had spent a decade searching unsuccessfully for new sources of beryllium, an uncommon metal urgently needed for an increasing variety of uses.

Beryllium, a relatively soft, silvery-white metal with a very low density, ranks 51st in crustal abundance and is about as common as tin. Although widely distributed, it rarely occurs in concentrations rich enough to mine. Elemental beryllium is an excellent X-ray window and neutron reflector; although only one-third as dense as aluminum, it is stiffer than carbon steel.

Beryllium had no uses until the 1930s when major advancements in X-ray, nuclear, and alloying technologies began to create demand.

By the 1950s, the metal had become vital for a variety of high-tech applications. Historically, beryllium’s sole source was beryl [beryllium aluminum silicate, Be3Al2Si6O18], which was obtained only from a small number of granite pegmatites. But most of these were already mined out, and the United States was forced to import beryl.

Then in 1959, a Nevada rockhound searching the remote expanses of western Utah collected some unusual, purple-and-white, chalcedonic nodules that he thought would make good cabbing material. Needing help with identification, he stopped by the offices of a mining exploration company. Although no one could visually identify the nodules, an on-site geologist decided to test them with a beryllometer, an early forerunner of today’s X-ray-fluorescence analyzers. To everyone’s surprise, the instrument detected beryllium

The rockhound had found these nodules in outcrops of altered tuff at Spor Mountain in Utah’s Juab County. Small amounts of beryl were known to occur in Spor Mountain rhyolite, but no form of beryllium had ever been found in tuff. Laboratory analysis of a nodule confirmed the presence of beryllium. Although, not as beryl, but as tiny yellowish, orthorhombic crystals of bertrandite [basic beryllium silicate, Be4Si2O7(OH)2].

Core drilling soon confirmed that there was indeed bertrandite-rich tuff at Spor Mountain—and lots of it. Groundwater had leached beryllium from nearby rhyolite formations and redeposited it within thick layers of porous tuff. It appeared as tiny, disseminated crystals of bertrandite. Although the tuff graded only about 1.0 percent bertrandite, it occurred as a three-mile-long, one-mile-wide deposit that was shallow enough for inexpensive, open-pit mining.

After mining began at Spor Mountain in 1968, the United States immediately went from a beryllium importer to an exporter. Today, after 52 years of mining, Spor Mountain remains the world’s largest known beryllium deposit and the metal’s sole domestic source. This site produces three-quarters of the 300 tons of elemental beryllium

produced worldwide annually.

Small, beryl-rich pegmatites are still mined in China, Mozambique, and Brazil. Together, these nations account for about 20 percent of global beryllium production. Driven by record demand, a single pound of refined elemental beryllium currently costs about $400.

While beryllium remains vital for many X-ray and nuclear applications, its most significant uses are specialty alloys with copper, aluminum, and nickel, mainly for aerospace applications. Because of the remarkable lightness and stiffness of these alloys, aircraft and space-vehicle masts weighing just six pounds can support 95 pounds of instrumentation. And because metallic beryllium polishes even brighter than silver, it is an ideal material for space-telescope mirrors.

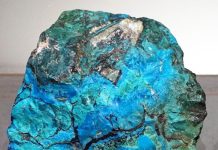

Beryllium is also used in automotive air-bag impact sensors, supermarket laser scanners, and computer hard drives. Racing bicycles that cost $12,000 or more are built with aluminum-beryllium frames that weigh only 1.5 pounds. Lapidaries now refer to the purple-and-white chalcedonic nodules as “Tiffany stone.” The nodules led to the discovery of the Spor Mountain bertrandite deposit 62 years ago.

These nodules consist of purple fluorite, common opal, quartz, manganese dioxide, and small amounts of bertrandite. Although most are destroyed in mine crushers, small quantities occasionally become available at gem-and-mineral shows and rock shops.