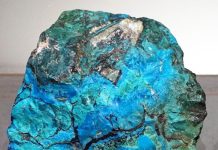

Borax is perhaps the best-known of the borates, a group of 45 boron-containing minerals that are a subclass of the carbonate mineral group. Borates contain boron and oxygen in hydrated combinations with one or more metals.

The household-cleaning product, Twenty Mule Team Borax®, has been on store shelves for 130 years. Its familiar logo, a 20-mule team hitched to two 15-ton capacity freight wagons and a water wagon, depicts one of the frontier West’s greatest feats of mine haulage—the grueling 165-mile-long desert journey to haul borax from mines in California’s Death Valley to a railhead during the 1880s.

Although widely disseminated in trace amounts, large, economic borate deposits are rare and found only in arid regions where boron-rich runoff water seasonally evaporates from intermittent lakes to form concentrated, layered deposits of borate minerals.

California Mining

The world’s largest borate deposits are in California’s Mojave Desert. Before their discovery in the 1870s, borax, then known as “tincal” (TING-kal) was imported from Tibet and Italy for limited (and questionable) uses in medicinal remedies.

The modern borax industry was born in the 1880s when miners began developing California’s deposits. By the early 1890s, Twenty Mule Team Borax® had become the preferred laundry and cleaning product across America.

California has four commercially important borate minerals: borax [hydrous sodium borate, Na2B4O5(OH)4·8H2O]; colemanite [hydrous calcium borate, CaB6 O11·5H20]; ulexite [hydrous sodium calcium borate, NaCaBO 6 (OH)6 5H2O]; and kernite [hydrous sodium borate, Na2 B4 O6 (OH)2·3H2O]. All occur in close association.

Borate Minerals

Borax, kernite, and colemanite form white or colorless monoclinic crystals. Ulexite crystallizes in the triclinic system as radiating aggregates of needle-like crystals and vein-type layers of closely packed, fibrous crystals, the latter displaying an interesting optical phenomenon. When inch-thick slabs of fibrous ulexite are polished flat on both sides and perpendicular to the fibers and placed on a printed page, a clear image of the print appears on the top plane. Similar to fiber optics, ulexite’s long, needle-like crystals transmit light longitudinally, hence its nickname “TV rock.”

Recovering Borates

Borates are recovered by brine evaporation, solution mining and open-pit mining. Brine miners pump underground, borate-rich brines into surface ponds for evaporation; solution miners inject superheated water into underground borate beds, then pump the dissolved borates to the surface for evaporation; and open-pit miners use large earth-moving equipment to dig shallow strata of borate minerals.

The borate minerals are dissolved in water, purified, and recrystallized. Borax, ulexite, colemanite, and kernite are then converted into chemical borax [partially hydrated sodium tetraborate, Na2H 4B 4O9nH2O]. This is a popular cleaning agent that, when dissolved in water, forms an alkaline, antiseptic solution used as a household disinfectant, laundry detergent, and water softener.

Industrial Uses

In industry, borax is a key component of Pyrex®-type, heat-resistant glassware. It is also used in paints, motor oils, enamels, ceramic glazes and coated paper. An excellent metallurgical flux, borax is the standard coating on welding rods.

In the now-outdated, qualitative “borax-bead” test, borax was mixed with ground samples of metallic minerals or ores, then heated to incandescence. The molten mix coalesced as tiny metal-borate beads with specific colors that indicated the presence of different metals.

Borax is also converted into boric acid [H3BO3], which is used medicinally for its astringent and antiseptic properties, and into boron carbides for manufacturing boron steels and exotic alloys.

Boron, California

The world’s largest borate mine is the Boron Pit, a 700-foot-deep, open-pit mine near aptly named Boron, California, which exploits a massive borate layer 1.5 miles long and 200 feet thick. Each year, the Boron Pit recovers one million tons of mixed borate minerals from three million tons of ore to account for half the world’s borax output. Thanks to the Boron Pit, the United States is self-sufficient in, and a major exporter of, boron minerals and compounds.

Today, borax is hauled from mines in 100-unit trains of 270-ton-capacity hopper railcars—a far cry from the 20-mule team wagons of the 1880s.

This story about borate minerals previously appeared in Rock & Gem magazine. Click here to subscribe. Story by Steve Voynick.