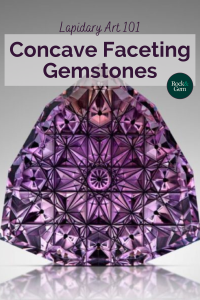

Concave faceting gemstones is a carving technique that has been used for many years and is now gaining popularity in the jewelry market because of its wonderful designs and light-bending capabilities. Where faceted gemstones have flat surfaces and cabochons have domed surfaces, the concave facet, or cut, is recessed, creating a scallop, groove, dimple or ring recessed into the gemstone. Using a combination of concave cuts will both embellish and change the light patterns, creating a unique and beautiful gemstone.

Concave Faceting Gemstones in the Industry

Concave gemstones are not new to the gemstone industry. They have been used for many years. I recommend reading Henry Hunt’s book, “American Lapidary – Designing the Carved Gemstone” as a great introduction to carving gemstones The book also has groundbreaking examples of work from the early pioneers, Lew Wackler, Steve Walters, Henry Hunt, Michael Dyber and Dalan Hargrave.

The concave gemstone is usually a combination of both flat and recessed facets with the recessed facets traditionally being placed on the pavilion of the gemstone. These gemstones are now gaining popularity with cutters for various reasons, including better cutting techniques, refined tools and understanding of light movement within the gemstone and gemstone style evolution.

Courtesy Mark Oros

Creating the Basic Shape

To create a concave gemstone, one usually starts with a regular flat-faceted gemstone. Cutting flat facets on a gemstone is done using a faceting machine that is comprised of four main components, the base of the machine, laps for grinding and polishing the gemstone, a mast for holding the gemstone and providing angle and index settings and the gemstone itself. The gemstones pictured in this article were initially flat faceted using the ULTRA TEC V5 faceting machine.

The faceting machine is used to create the basic gemstone shape. Once the shape is made, the mast and gemstone are transferred to the ULTRA TEC Fantasy machine. Concave faceting is sometimes called fantasy faceting. They are both the same technique using different names.

The ULTRA TEC Fantasy machine is a sophisticated special-use lathe with an attachment for the faceting mast/ gemstone and concave tools. It has multiple options for cutting at different axes, angles and orientations. The Fantasy machine is a versatile lathe for carving gemstones and was designed by leading gemstone artists. Although it appears to be complex in operation, once you use it a few times, it becomes intuitive and a joy to work.

Concave Faceting – Cutting the Facets

Once the pavilion of the gemstone has been faceted to the proper grit, the mast and gemstone are transferred and aligned on the Fantasy machine. Then a series of tools and mandrels are used to cut and polish concave facets. Concave facets describe any recessed carving into the gemstone regardless of shape, size or tool used.

There are multiple tools used to apply the concave facets. The standard tools are a cylinder mandrel, angle slitting tool, bullnose mandrel and circle cutters. These tools come in a series of grits, from rough to very fine, used initially to cut the concave and then, by using finer and finer grits, to bring the concave up to a perfect polish.

Along with standard tools, there is a variety of tools used for carving. Diamond dentistry tools are popular in creating concave facets. Using the mast, lathe and tools, one can cut and polish recessed facets, however, the gemstone cutter needs to have a design in mind for the gemstone before starting the fantasy cuts.

Gemstone Design

The standard gemstone design is a well-thought-out and developed design that allows transparent gem material to reflect light, sparkle and easily be set in jewelry. The gemstone faceter needs to be cognizant of these desired properties and not diminish them during the concave process, but rather enhance them. This is done by understanding the properties of the gemstone’s geometric appearance and light properties.

The geometric shape of the gemstone can be embellished by faceting recesses into the girdle. The concave facets cut into the girdle will create a new outline for the gemstone. The girdle recesses can be simple like a single angle cut to the top of a heart design. One can do more complex cutting by taking an octagonal shape and cutting eight small scallop shapes into the girdle to give the gemstone a star shape. I have even used a drop/pear shape and cut angle facets into the girdle to give the gemstone the look of a knapped arrowhead.

Changing the Light

Not only does the recessed facet change the shape of the gemstone, but it also changes how the gemstone looks by moving the light entering and reflecting out of the gemstone in new ways. The three most prevalent ways that light enhances a gemstone are by returning the light via reflection to brighten the gemstone, breaking up the returning and reflected light to cause sparkle/scintillation, and bending the light to show different colors with dispersion. Adding concave facets to the gemstone changes these three main lighting phenomena with each facet. Now the light moves around differently.

In addition, two more attributes can be added to the gemstone that are usually avoided in traditionally faceted gemstones, windowing and extinction. Windowing is the ability for the gemstone to pass light directly through the gemstone as opposed to reflecting it back to the viewer to make the gemstone bright. Although windowing is avoided in traditional gemstone faceting, it can play a significant role in how a concave gemstone looks and behaves. Extinction is where the light neither reflects nor windows but creates a black surface illusion in the gemstone. Both windowing and extinction can be used to add very dramatic looks to a gemstone by adding both clear and black portions to the gemstone design.

Courtesy Mark Oros

Beyond the Faceting Machine

There are other ways to create concave facets and designs. A traditional lathe can be used with the proper cutting and polishing tools. A skilled gemstone carver can create precision recessed cuts in a gemstone using a hand tool, like a Foredom carving handpiece. I sometimes use a handpiece to put in additional concave facets or change the shape of the ones put in by the Fantasy machine.

There is also the rose engine, a specialized lathe. The rose engine has been used for centuries in lathe design work for both metal and wood. Nolan Sponsler, gemstone artist and goldsmith, introduced the rose engine into the gemstone world and is now championing its use in concave faceting. The adaptation, fabrication, support and enhancement of the rose engine to the gemstone world, has been done by David Lindow at Lindow Machine Works.

Courtesy Mark Oros

Concave Faceting – A Basic Process

Here is the basic process I use for concave faceting gemstones.

- Cut the gemstone pavilion with flat facets following a traditional gemstone design. I take the gemstone up to 3,000 grit.

- Move the mast and gemstone to the Fantasy machine and align.

- Decide on the type, location and number of concave facets for the design.

- Cut the concave facets and bring them up to at least 1,200 grit.

- Take the gemstone off the mast and bring it to the carving station where I pre-polish and polish the gemstone’s concave facets using diamond paste, oil, brushes and felt.

- Put the gemstone back on the mast and return the mast to the flat faceting machine.

- Recut the remaining flat facets taking out any chips and grooves.

- Pre-polish and polish the flat facets.

- Transfer the gemstone and facet the crown and table.

Keep in mind that putting concave facets into expensive gemstones will reduce the carat weight and value of the gemstone. In return, one hopes the unique design and play of light in the gemstone will not only recover that loss of value but also add to the original value of the gemstone.

Using these tools, techniques and designs allows the gemstone artist to present a more sculptured piece of gemstone art. This type of gemstone design is gaining popularity in custom gemstone and jewelry circles. It is just beginning to be seen in the mass-produced gemstone market. Hopefully, this introduction to the area of evolving gemstone art inspires you to explore it further.

This story about concave faceting previously appeared in Rock & Gem magazine. Click here to subscribe. Story by Mark Oros.