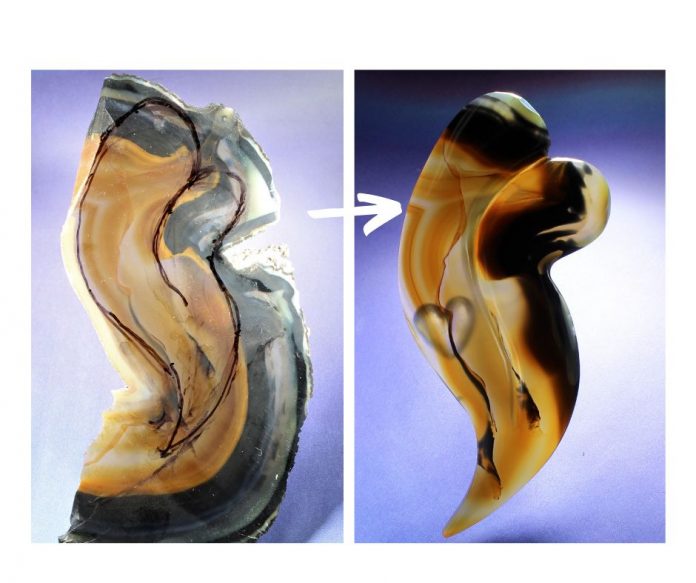

I had a slab of my favorite Brazilian Agate from previous projects that had an irregular shape and some defects that had to be taken into consideration. The most obvious shape in my imagination that would fit was a distorted heart shape which wouldn’t be available in most regular templates, so I sketched it on the slab to fit around the slab’s defects.

Making The Heart

I trimmed and ground the preform to that shape. I had planned on having a curved groove going from the top between the upper lobes to the lower part of the heart shape.

I sketched the groove and used a 1/4-inch diamond “V” bur to grind a small groove following that trace. I enlarged the groove with a 3/4-inch “V” bur. I wanted the sides of the groove to have a curved outward shape rather than a sharp edge, so I used a 3/8-inch diameter diamond bur to carve the curve.

All of this grinding on the groove resulted in many dips and bulges from the hard diamond burs. I used some silicon carbide carving block shapes to sand down these unwanted surface defects. These blocks were made from pieces of old silicon carbide grinding wheels. These carving blocks can be found online or fabricated from a grinding wheel segment that is shaped to fit deeply into the curve.

After I finished sanding the groove sides with a 600-grit sanding block I polished them with a 5/8-inch diameter wood bur shaped into an inverted cone while utilizing cerium oxide polish.

The next step involved finishing the rest of the cab by doming the front of the cab using standard cab-making steps.

Making The Second Heart

As I was conceiving this project, I had a vision of it having an additional but smaller heart shape carved from the back of the finished shape would allow it. As the cab evolved, it became clear that the smaller heart shape could be accommodated. I used a small heart shape template to draw the heart shape on the back of the cab with a fine-tipped sharpie.

Using a 1/8-inch round diamond bur, I started grinding the heart shape from the back.

As I was grinding the shape, I frequently checked the depth of the carving. Because the material was quite translucent, I didn’t have to go very deep to get the heart shape to show through to the front. I was able to do most of the carving with the 1/8-inch bur but I still had to use a much smaller diamond bur to carve the bottom tip of the heart shape.

Finishing Up

The final steps included sanding the interior of the heart shape with a shaped wood bur and 220 and 400-grit abrasives. It also included polishing the inside with another shaped wood bur and cerium oxide polish.

As I was working on this distorted heart shape I could hear its disappointment about not getting to be a regular heart shape. When I finished giving it a heart of its own it ended up with a broken heart.

|

This story about how to make a double heart shape cab previously appeared in Rock & Gem magazine. Click here to subscribe! Story by Bob Rush.