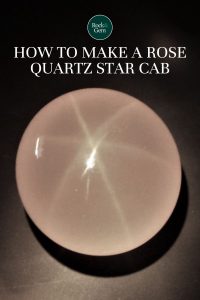

Many materials can exhibit a star including rose quartz. This material is rather abundant but rarely clear from fractures and other internal defects. It is rather difficult to find pieces with good enough clarity to make a very big cabochon or sphere especially one with the star in the center top of the cab.

About Rose Quartz Stars

Rose quartz is a massive variety of quartz that is found worldwide. Some pieces exhibit asterism which is the ability to display a six-ray star. This is because of a region of single crystals embedded within the massive material.

The origin of the stars is dumortierite-like nanofibers producing both the rose coloration and the asterism. The asterism is best seen from a single-point light source like a flashlight or preferably the sun. LED lights are usually a diffused type and won’t work for evaluating the rough.

The nanofibers are 100 to 500 mm in diameter. They are so small that it takes hundreds bundled together to approach the thickness of human hair. Often, they are placed so that you can only see a single bar of light which gives a cat’s-eye effect. There will often be one strong bar and two weaker bars that show asterism.

Making the Sphere

The most important thing is selecting a piece of rough that has few fractures showing. These fractures usually are healed but visible and many will be fractures that reach the surface.

It is very difficult to observe a star pattern in the rough piece and equally difficult to get the star pattern centered in a cabochon. If I can see a secondary wispy sheen on the surface, I’m fairly confident that a star pattern can be found in the piece.

Selecting Rough

The piece that I selected was about 1½-inches in the longest dimension. I was expecting a 1-inch diameter finished sphere. I like to make spheres from this material because it is easy to see the pattern and if I want a cabochon then I just cut the sphere in half perpendicular to the pattern.

I started shaping on my diamond grinding wheel until it was close to a sphere shape. I then shaped it with a diamond core drill mounted in a drill press. The core drill should be two-thirds of the diameter of the sphere. I dipped the sphere into water frequently and moved it around as the drill shaped the piece.

The next step involved using a small flat lap machine that has a variable speed feature. I fabricated a sphere cup from a piece of round steel rod. It has a threaded shaft that screws into the lap mounting hole on my machine. On the other end, I drilled a large hole to make a cup shape. If you know someone who has a machining lathe, they can make one of these. I can’t find a source for these online.

With the sphere cup mounted on the flat lap, dip the sphere preform into a wet slurry of 100 grit tumbling media and roll the sphere around in all directions in the spinning cup. Wear gloves for the sanding steps because the grit waste will stain your hands. Stop frequently to check for remaining flat spots. When they are all gone clean the cup and continue with 220 and 400-grit media until the surface shows no defects.

At the end of the sanding steps, mount the pre-form on a dop stick and proceed to the polishing step. You will have to rotate the sphere to get polish on all of the sides. I did find the star, but it was difficult to photograph.

|

This story about how to make a rose quartz star cab previously appeared in Rock & Gem magazine. Click here to subscribe! Story by Bob Rush.