Lapidary projects often require visualization of the finished project formed from a rough slab. You can lessen that leap of faith by learning how to visualize and develop a pattern. Quite often as I am looking through my crates of slabs, I’m looking for a specific pattern or shape that I have in mind for my next project. At other times, the slab finds me.

The Right Slab

This time the slab was somewhat obscured because it was sawn with a bad blade and the surface was rough. I had to use a coarse sanding belt to get it smooth enough to evaluate the lapidary pattern.

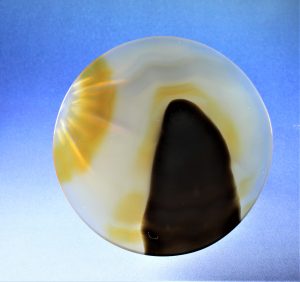

What caught my eye early on was the orange partial circle on the upper left and an obvious dark mountain image dominating the overall slab. There was a faint orange halo cloaking the mountain.

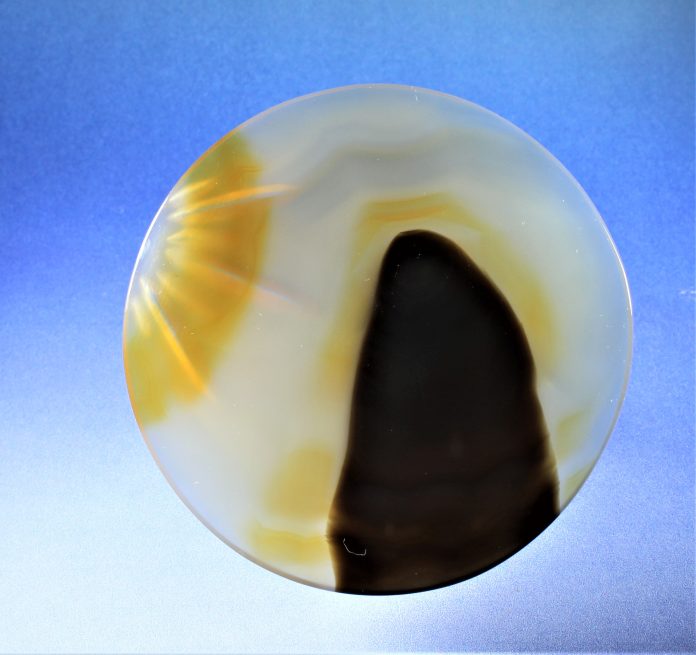

The orange circle on the left immediately triggered my favorite pattern to work with – the sun. The backside had a small druzy crystal pocket but it was poorly positioned and it detracted from the overall pattern. What became evident was that a circle was the best and only option that could capture all of the elements in the pattern.

Getting the Circle Right

Using a large circle lapidary template, I drew the desired shape on the slab. Circles are somewhat difficult to get correct, so I rigorously followed the template marks. After getting the shape completed, I marked the desired height of the girdle by laying a sharpie on its side and adjusting the height of the cab by placing thin sheets of cardboard under it. I generally divided the girdle in half with the dome going down to the mark. Finishing the cab front was done using standard lapidary procedures.

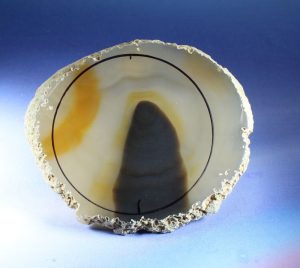

Making the Most of the Sun

To enhance the sun image, I decided to carve the back with images depicting rays of light emanating from the sun image. I sketched the rays on the back with a sharpie and carefully ground them with a small diamond “V” bur held in my Fordom handpiece. To cool the diamond bur, I used a section carved from a large soda bottle about ¾” deep filled halfway with water. I frequently dipped the cab in the water as I was carving the grooves. As I was grinding, I looked from the front to check how well the grooves looked and how deep they were.

Sanding the Grooves

When I finished grinding the grooves I was ready to sand them. I sanded them with a knife-edged wood bur using a paste of 220-grit tumbling grit. I followed this with a new wood bur and 400-grit paste.

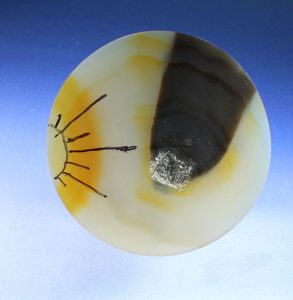

Finishing Up

The final step was with a new knife-edged wood bur and a paste made of cerium oxide polish. All three of these burs are made from a wood dowel shaped with a coarse file. The final product definitely ended up as I had visualized it would!

|

This story about lapidary project visualization and pattern development in a slab previously appeared in Rock & Gem magazine. Click here to subscribe. Story by Bob Rush.