Making cabochons can seem like a daunting task to a beginner. Here are some of our tips and tricks for making your own homemade cabochon-making tools.

For the last two weeks, I have been teaching advanced lapidary bench classes with the California Federation of Mineralogical Societies at their beautiful, forested site called Camp Paradise in the Sierra Nevada mountains. Multiple subjects are taught there including faceting, lapidary, advanced lapidary, soft stone carving, silversmithing, lost wax casting enameling and fused glass.

As a part of my classes, I teach making the tools used in carving the back and fronts of cabs. To my knowledge, these techniques are not commonly taught elsewhere.

Materials Needed

There are four different materials that I use to make my tools:

- Wood dowels or wood wheels

- Cratex rubberized wheels (with silicon carbide embedded into the rubber wheels)

- Silicon carbide Mizzy wheels

- Silicon carbide sanding blocks

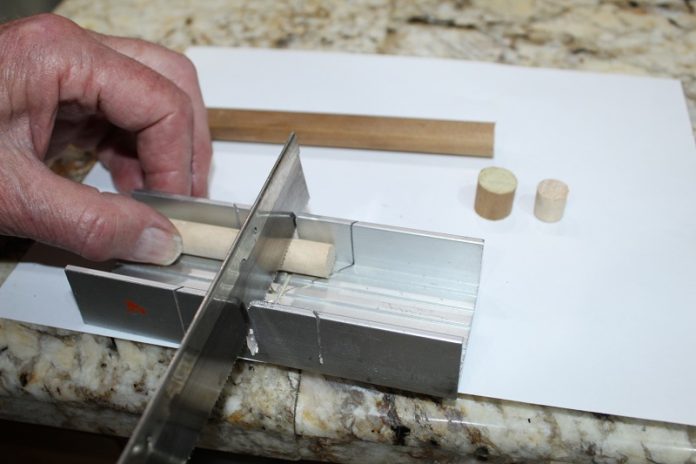

Wood Dowels

The wood dowels that I use are one-half-inch in diameter. If I have a small hole to work on I use a three-eighth-inch diameter dowel. I cut them into one-half-inch length pieces and drill a small hole into the end to accept the screw end of a half-inch threaded point mandrel. I then shape them by spinning the dowel in a flex shaft unit and applying a coarse wood rasp. I use these rounded shapes to sand and polish the decorative holes that I carve into the back of cabs. To sand the sides of a groove I shape the inside of a wood wheel and use tumbling grit for the sanding media.

Shaped Wheels

The second tool that I use is made from Cratex rubberized wheels. I shape them on a diamond T-bar stone wheel dresser by holding it at an angle to the back side of the spinning Cratex wheel. I use this wheel to sand the sides of a groove.

The third tool that I make is a shaped silicon carbide Heatless Mizzy wheel. It is shaped in the same manner as the Cratex wheel. This wheel is used to carve a groove in a cab.

Silicon Carbide Sanding Blocks

The fourth tools I use in my cab-making process are silicon carbide sanding blocks. They are made from silicon carbide material and are about three-eighth-inches square and four inches long. They come in various grits from about 220-grit through 600-grit. They also come in soft binder and hard binder which is determined by how the grit is bound together. I only use the hard binder. They are used to smooth out the lumps and low places in a carving after the grinding steps. I use them to round out the top shoulder and the V of a V-shaped groove.

I cut up silicon carbide grinding wheels on my slab saw to make silicon carbide sanding blocks. When I have finished carving the top of rounded grooves on a carving, I shape the end of a silicon carbide carving block with a cylinder diamond bur to sand the top of the rounded grooves.

I find that by making my own specialized tools I can make the work on my carvings go quicker and with a better overall outcome.

Steps By Photo          |

This story about making cabochons previously appeared in Rock & Gem magazine. Click here to subscribe. Story by Bob Rush.