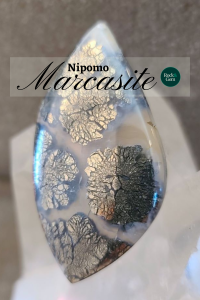

Although marcasite is found all over the world, Nipomo is most famous for its flowery patterns of shiny metallic gold-colored marcasite floating in chalcedony.

Where is Nipomo?

Nipomo is a small rural suburban town on the central coast of California, a favorite rockhounding spot for years. Today, many of the stones from this region have become exceedingly scarce. Many of the digging locations for this marcasite are on private property. It was allowed at one point to collect with the owner’s permission, but a few rockhounds ruined it for the rest by trespassing, trampling newly-grown crops, and opening and closing gates not allowing cattle to get to their water sources. As a result, this material hasn’t been dug for a few decades.

Characteristics

Nipomo marcasite has many agate characteristics, the favorites are the golden plumes in clear agate. The agate can also be milky to white and have translucent reds to browns.

When buying marcasite, it’s difficult to tell what you will get. Many times the metallic marcasite is in spots throughout, giving it that Dalmatian effect. Other times you can find pieces with almost 90 percent metallic marcasite with little spiderwebbing agate. If you are seeking certain colors or grades, buying slabs might be the way to go. Although at this point, it’s tough to be too fussy over what you find since there’s not a lot out there.

When buying in the rough form, check the outer layer to see that it’s stable enough to cut. Marcasite with minimal agate can be very soft and crumbly and not yield a great deal of cabbing material.

Slabbing & Designing Preforms

Slabbing & Designing Preforms

When starting to slab rough, there’s generally no right or wrong direction. It’s probably best to load the saw with the flattest spots possible for the vice to grip. If after a couple of slabs, patterns appear that are going in a different direction than you’d rather try to capture, reposition the rock in the saw and cut from a different angle.

Cabbing this material is not difficult, but there are a few precautions to look for when designing your preforms. The marcasite on the outer edges of the rough rock that was exposed to the soil may be very soft and crumble away when trying to trim out your cab shapes. Always bench-test each one ahead of time, so that you can make adjustments in design as needed. If you design from the center of the slab with a great deal of agate content, you should be fine, with little to no pitfalls.

Cabbing

Cabbing

I start cabbing on the 80-grit steel diamond wheel to shape and dome my preforms then move to the 60-grit soft resin wheel. Once you reach the soft resin wheels, you should continually check your work as you go, because the hardness differences could lead to undercutting or pitting.

Depending on the desired outcome, some lapidaries like to stop and stabilize their cabs to fill in the pits or gain an equal hardness so that the surface remains even across the finished cab.

Otherwise, you can continue and keep the natural look and move your way to the 280 soft resin wheel. This is where the majority of the work will take place. Be sure to constantly dry off the material and check for scratches. Do not move forward until they are all gone at this stage.

After this, everything is routine to any other agate. Go from the 600-grit, all the way up to the 14k-grit wheel and this will leave you with a gorgeous polished agate with brilliant shiny metallic marcasite that just gains a ton of attention.

Over time, marcasite tends to tarnish, so a light polish with Zam Polishing Compound will give an added polish and protectant. This will most likely need to be done again and again over time to keep it shiny, as oils and air will continue to tarnish this material.

This story about Nipomo marcasite previously appeared in Rock & Gem magazine. Click here to subscribe. Story by Russ Kaniuth.