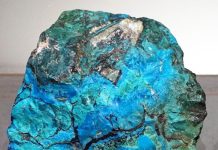

Phosphosiderite was originally discovered in the mid-to-late-1800s, and though it’s generally just a monochromatic colored stone, it’s been a fan favorite because of its “purple orchid” coloring. Phosphosiderite isn’t a gemstone, but a mineral. Its name comes from its main components —phosphate and iron. The word sideros in Greek means iron.

Where to Find & Purchase

Phosphosiderite is rather rare and can be found in gem-grade stone that can be faceted. The majority is an opaque mineral that’s generally colored pink to a lilac purple that can be cabbed. It can also feature spider-webbed yellow cacoxenite veins, an iron aluminum phosphate mineral that gives it a wonderful pattern when designing cabochons.

When purchasing phosphosiderite rough, you can usually see what you’ll get from looking at the outer stone, but you can never gauge how much webbing and patterns will be in the center until slabbing it. It will change with each slab cut.

Tips For Working With Phosphosiderite

Tips For Working With Phosphosiderite

When slabbing this mineral, note that it is very soft, (3.5 to 4 on the Moh’s scale) and should be cut with a thinner blade if possible. This type of mineral can also have its color altered if cutting in oil, so I usually cut the majority on a smaller trim saw using water as the coolant. If you cut with oil, it’s best to wash the slabs off immediately before the oil has the chance to soak in and darken the stone. Also be aware that in a short time, that oil will dry and the color will fade, but more importantly, it will dissipate at different rates that affect the other inclusion minerals, giving it a splotchy look, so it’s best to wash it all out ahead of time.

Once you have cut your slabs and are ready to draw out your preform shapes, do not use a Sharpie ink pen to draw. It will soak up the ink almost 2mm deep. It’s best to use a scribe or pencil, that marks just the surface.

When cabbing phosphosiderite, you must have extra water flow on your machine. Much like serpentine, this mineral will foam and become ver y frothy when grinding your shapes out, making it not only messy but incredibly hard to see your design lines.

I like to keep a small dish of water next to the machine, so I can rinse off the excess white foam it creates, so I can see where I’m grinding.

Shaping and Finishing

Shaping and Finishing

Depending on your setup, you can use a steel 80-grit wheel to start shaping your cabs, but since this material is so soft, just do it with a gentle touch. I would suggest using a steel 220-grit if you have one. Once I have shaped and domed my cabs on the steel wheel, I move ahead skipping the course wheels, and start my sanding and smoothing on the 280-grit soft resin wheel. Usually, I would use my 280-grit wheel to remove all the existing scratches before moving ahead, but in the case of an exceedingly soft material, I would use my 600-grit to remove the remaining scratches, and then start my polishing on the 1200-grit wheel.

Again, depending on your setup, you can move onto a 3k or 8k grit wheel, and it should start to give you a beautiful glossy finish, and you can end on the 14k grit soft resin wheel and not have to go any further.

If you choose to use a final polishing compound, like Zam or cerium oxide, go slow, and don’t allow the stone to heat up, as it may create unwanted surface fracturing. Just a quick run with a felt tip will help obtain a wonderful mirror shine on your cab.

This story about phosphosiderite previously appeared in Rock & Gem magazine. Click here to subscribe. Story and pictures by Russ Kaniuth.