Rhodusite, also known as Magnesio-Riecbekite, is a rare enchanting blue fibrous stone found on the Kola Peninsula of Murmansk Oblast, Russia. Rhodusite is an amphibole mineral that grows needle-like crystalization formations, much like tiger’s eye and Marra Mamba. It has a wide array of blues that are also a bit chatoyant, which resembles pietersite, a member of the blue gems and minerals list, and gives it the nickname Russian Pietersite.

Finding Rhodusite

Finding Rhodusite

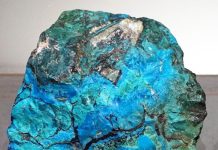

Though this material is a bit rare, it still can be found in the marketplace, either at shows or online sales. The rough is all generally the same, chunks of large compacted strands of beautiful blue stone.

Slabbing

Slabbing this material can be done in a couple of ways to achieve a few different patterns. You can cut top to bottom with the strands, or you can cut across the grain. Rhodusite has a significant hardness, but it can be tricky to cut either way, as it likes to separate at times.

With each slab cut, no matter which direction you cut in, always bench test and see if it is showing fractured areas that want to separate. First, wipe a light coat of water across the top of the slab, and watch as it dries, the surface will dry quicker and the fractures holding water will start to appear. It’s also best to flex the slab in hand and see if it will break. Utilize the pieces to cut out your preforms. This material will generally dictate what size and shape of each cab. You will find nice solid pieces to create your own patterns, but many times the stone will choose for you.

Cabbing

Cabbing

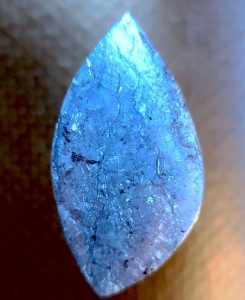

When starting to cab, I chose a different way to shape most of my cabs. The 80 grit steel wheel can at times be a bit too aggressive and break the slab into unwanted pieces, so I start on a 60 grit soft resin wheel and slowly shape and dome each preform. I’ve had much better luck using the soft wheels to start with far less breaking or fracturing of the preforms. Many times bits or strands like to chip off the face of the cab, so cut your preforms a bit on the thick side, this way you can always address this when doming the top. You may have to sand down a little further than expected to smooth out any small pits that you obtain while shaping your cab.

Once the preform is shaped and domed, I go to either a 140 soft resin wheel and finish smoothing it out, and jump right ahead to the 280 grit soft resin wheel. This is where you want to smooth it out and make sure any pits have been sanded out and scratches removed before moving on.

The remainder of the way is relatively simple, continue to the 600 grit, all the way up to the 14k grit wheels. This will give you a nice high-luster shine. To get a nice polished end result, try using some Zam polishing compound on a felt tip using your Dremel or Foredom rotary tool, and this will instantly give you a nice glossy finish.

This story about rhodusite previously appeared in Rock & Gem magazine. Click here to subscribe. Story by Russ Kaniuth.