By Steve Voynick

One of my favorite roadside overlooks is located 15 miles east of Silver City, New Mexico, on State Highway 152. The view, often veiled by dust rising from the endless procession of ore-haulage trucks far below, takes in the huge Santa Rita open-pit copper mine. Also known as the Chino Mine, the Santa Rita Mine, 1,500 feet deep and 1.5 miles across at the rim, was created by a century of drilling, blasting, and hauling more than a trillion tons of overburden and ore.

Sights of Santa Rita

Over its long life, Santa Rita has yielded 8 million tons of copper and it still producing 140,000 tons of the metal each year. Its history is equally impressive. First worked by Spanish miners in 1804, Santa Rita is the oldest operating mine in the United States. It’s also the place where several landmark advancements in mining technology got their start.

Santa Rita is just one of the attractions near Silver City that are related to mining, minerals, and geology. Others include the Tyrone district, the site of another big copper mine and a historic turquoise mine; and the Fierro-Hanover district, a former source of iron and zinc, the setting for the 1954 movie “Salt of the Earth,” and a collecting site for interesting ore and mineral specimens. Also nearby are two unusual geological features, one a regional landmark, the other a state park.

Silver City itself is the hub of a half-dozen mining districts. Well off the interstate highways, it is located in southwestern New Mexico at an elevation of 5,900 feet in the southern foothills of the Mogollon Mountains. Founded in the 1870s as a rough-and-tumble silver-mining camp, Silver City now has a population of 10,000 and a beautifully restored, historic downtown. It’s an artists’ colony, a tourist destination, the home of Western New Mexico University, and the perfect base from which to visit the area’s mining attractions.

Mineralization Origins

The story of any mining town starts with its mineralization. At Silver City, the emplacement of ore minerals began some 65 million years ago with the Laramide Orogeny, the mountain-building event that uplifted the modern Rocky Mountains and fractured the crust over much of what is now the western United States. Magma later moved upward through these fractures to form intrusive bodies consisting of porphyritic diorite, granodiorite, and monzonite. The term “porphyrytic” refers to igneous rock with conspicuous crystals (phenocrysts) amid a finer-grained groundmass.

The rising magma was accompanied by hydrothermal solutions rich in copper, gold, silver, lead, zinc, and iron. Surging through fissures in the porphyritic intrusions and adjoining country rock, these solutions precipitated minerals in veins and bodies of disseminated particles.

The main intrusive body, which geologists call the Santa Rita Stock, was emplaced about 58 million years ago. Initially, its associated, low-grade copper-sulfide mineralization occurred near the top of the stock. As erosion reduced the surface, the upper portion of the sulfide mineralization became oxidized. Groundwater then interacted with pyrite to form weak sulfuric acid, which leached the surface copper minerals. In the process of supergene enrichment, copper-rich solutions percolated downward to the water table to precipitate copper in massive, copper-porphyry deposits—porphyritic rock that is secondarily enriched by copper mineralization.

These huge copper-porphyry deposits contained disseminated particles of the sulfide minerals chalcopyrite and chalcocite, while the adjacent, altered country rock sometimes hosted high-grade veins and bodies of zinc, iron, lead, and silver minerals. They were capped by oxidized surface occurrences of azurite, malachite and, in a few places, turquoise.

Outcrops Provide Valuable Commodities

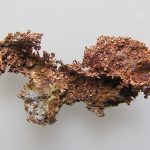

Long before the arrival of Europeans, Native Americans, attracted to the bright, blue-

green outcrops of azurite and malachite, mined turquoise and native copper. Both were valuable trading commodities. They also fashioned some of the turquoise into beads for jewelry, and hammered the copper into such utilitarian objects as arrowheads and knives.

Some historians suggest that early Spanish explorers may have mined small amounts of turquoise near the present-day Silver City area. The first documented reference to the local mineralization appeared in 1799 and tells how friendly Apaches led Spanish military officers to the native-copper occurrence at Santa Rita. Astounded by the abundance of native copper and malachite, these officers formed a partnership and successfully applied for a Spanish land grant. Called the Santa Rita del Cobre (Saint Rita of the Copper) grant, it is the region’s first record of formal land ownership.

The Spanish began mining native copper and high-grade malachite ore in 1804, shipping it to Chihuahua and Mexico City. Each year, 200 mule trains carried some 3,000 tons of native copper and malachite south. After 1810, production declined due to Apache raids and the onset of the Mexican War of Independence. Nevertheless, between 1805 and 1840, Santa Rita provided almost all the metal for the Spanish and Mexican copper coinage struck at the Mexico City mint.

Mining activity increased after much of New Mexico became a United States territory in 1848. But although prospectors made encouraging finds, the area’s remoteness, coupled with Apache raids, and the Confederate invasion of New Mexico during the Civil War, delayed organized mining.

In 1870, prospectors struck silver at Chloride Flats and founded the mining camp that would become Silver City. The ore minerals of this small, but rich, deposit were mainly chlorargyrite (silver chloride), acanthite (silver sulfide), argentiferous galena (silver-bearing lead sulfide), and native silver. The biggest producer, the Breman Mine, yielded $1 million in silver in just four years. By 1900, silver production at Chloride Flats had topped $20 million.

Evolution of Prospecting Near Silver City

In 1875, prospectors discovered copper and turquoise in the Tyrone district in the Big Burro Mountains 10 miles south of Silver City. Native Americans had mined turquoise at this site for centuries, leaving behind trenches and shafts as deep as 40 feet. In the early 1880s, the American Gem and Turquoise Company opened the Parker Mine, the district’s first commercial turquoise mine. The company dug two long cuts to intersect a massive, six-inch-thick vein of solid turquoise—only to be disappointed by its softness and pale coloration.

The Azure Mine, which opened in 1891, had better luck and became the district’s largest and most successful turquoise mine. Its famed Elizabeth Pocket, the richest, single turquoise occurrence ever found, was 60 feet high, 40 feet wide, and 150 feet long, and contained veins and nuggets of turquoise in a soft, easily mined matrix of kaolin clay. The largest recorded nugget of pure turquoise weighed 10 ounces. When mining ended in 1915, the Azure Mine had yielded $4 million in top-quality turquoise.

In 1911, a United States Geological Survey field geologist described the Azure Mine turquoise as “. . . probably the finest ever found in the world. Much of it is a deep blue color, slightly translucent, and very hard so that it makes a fine wearing gem.”

Copper mining didn’t hit its stride until after the turn of the century. In 1906, mining engineer John M. Sully recognized the similarities between Santa Rita’s low-grade, copper-porphyry ores and those of Utah’s Bingham Canyon Mine. Bingham Canyon had just pioneered mechanized, mass, open-pit mining and was using the new, but still unproven, flotation-separation process to concentrate low-grade ores.

Confident that a similar approach would work with Santa Rita’s ore, Sully abandoned underground mining, formed and funded the Chino Copper Company, designed an open pit with steam shovels and railroad haulage, and installed a flotation-separation concentrator.

Open-Pit Progression

The Santa Rita open-pit began mining in 1910. Despite low-grade ore that graded only two percent copper, the mine was immediately profitable and, by World War I, had become a major source of copper.

By then, the Tyrone district had also come alive. In 1910, the Phelps Dodge Corporation consolidated the district’s many properties, sank three major shafts, and built the model company town of Tyrone. Replicating a Spanish village with Rococo-style, red-tile roofs and white-stucco walls, Tyrone was a vast improvement over the tin-roofed shacks of most other mining-company towns.

The mines boomed during World War I, only to shut down in 1921 amid low post-war copper prices. Phelps Dodge abandoned its new company town. Fifty years would pass before the Tyrone district again became a major source of copper.

The Fierro-Hanover district, just north of Santa Rita, opened on iron mining in the late 1880s. “Fierro” is a corruption of hierro, the Spanish word for “iron.” Its rich ore consisted of massive magnetite. Containing 60 percent iron, it made an excellent flux for the local copper smelters. The ore was also shipped by rail to feed iron smelters in Colorado.

When zinc prices rose after 1900, many Fierro-Hanover iron mines turned their attention to the district’s abundant sphalerite (zinc sulfide) ore. The district’s biggest zinc operation was the Empire Zinc Company’s Empire Mine at Hanover, which opened in 1915.

Strike Impact

In 1951-52, the Empire Mine endured a bitter, 15-month-long strike over the inequality of a dual-wage system that paid Hispanic miners less than Anglo miners. When a court order prevented the Hispanic miners from picketing, their wives took their places and eventually won a favorable settlement with the company. Amid Cold War fears of communist infiltration, the strike pushed the limits of prevailing race-relation and gender roles. Many observers around the country perceived the strike, which reduced zinc supplies during the Korean War, as an “un-American” activity.

The strike was memorialized in the 1954 movie “Salt of the Earth,” which was produced by blacklisted Hollywood artists. Many actors were district miners or family members who had participated in the actual strike. After its release, the movie was suppressed and rarely shown in the United States. Today, it has become a cult classic that provides poignant insight into the realities of zinc mining in New Mexico in the early 1950s.

Meanwhile, as picketers marched in the Fierro-Hanover district, the growing Santa Rita Mine continued to redesign the local landscape. When ore was discovered beneath the company town of Santa Rita, the houses were moved and the town site itself disappeared into the ever-widening pit in 1968.

Mining finally resumed in the Tyrone district in 1969, when high copper prices followed a successful, 20-year-long, core-drill exploration program. This time, Tyrone miners developed an open pit on a copper-porphyry deposit that was similar to, but smaller than, the Santa Rita deposit. Within 10 years, the original town of Tyrone disappeared into the expanding pit. A second company town of the same name was built several miles away. Production of 40,000 tons of copper per year continues today.

In the 1980s, the Santa Rita and Tyrone mines helped introduce a major advancement in copper recovery—large-scale commercialization of the SX/EW (solvent-extraction/electrowinning) process. SX/EW is a hydrometallurgical process that operates at ambient temperatures. It treats low-grade, oxidized ores, oxidized mill tailings, and roasted (oxidized) sulfide concentrates, all of which are found in abundance at copper-porphyry mines.

Mine Processes

SX/EW uses weak sulfuric acid to leach oxidized copper compounds. The recovered,

copper-rich leach solution is then mixed with organic reagents that extract copper by an ion-exchange process. In the final step, the copper in this concentrated, secondary solution is then electrolytically reduced to elemental metal.

SX/EW eliminates the need for smelters and, because oxides can be leached in situ, it has a relatively low environmental impact. To supplement SX/EW, newly developed, inexpensive “bioleaching” processes use naturally-occurring bacteria to oxidize copper sulfides in preparation for SX/EW copper recovery.

Today, the Santa Rita mine treats higher-grade ores by flotation separation and ships the concentrates to Arizona smelters; lower-grade ores are processed by SX/EW. The Tyrone Mine relies exclusively on SX/EW. The two mines, both owned and operated by Freeport-McMoRan Copper and Gold, Inc., now employ 1,000 workers on an $80 million annual payroll. Each year, they recover 180,000 tons of copper worth a billion dollars.

Since the 1800s, Silver City-area mines have produced 75,000 troy ounces of gold, 9 million troy ounces of silver, 150,000 tons of lead, 400,000 tons of zinc, and a large tonnage of iron—along with a whopping 10 million tons of copper.

While the sprawl of Silver City now covers much of the old Chloride Flats district, the area’s mining heritage is preserved at the Murray Ryan Visitor Center where displays include mining-related murals and a 100-pound, anode-copper sphere from one of the area’s historic smelters. The Western New Mexico University Museum also has several mining- and mineral-related exhibits, as does the Silver City Museum.

The town of Hurley, a former smelting center near Santa Rita, features a restored company store with mining-related attractions.

Modern Opportunities to Explore

Although most mining properties, both active and inactive, are posted against entry, there are still places to collect mineral and ore specimens. One of the best and most accessible is along New Mexico Route 356 that passes through the Fierro-Hanover district.

At the old town of Hanover, the steel headframe of the long-inactive Empire Mine towers above waste dumps that spill onto the shoulder of the road. An old rail grade with several ore-loading ramps parallels the road. At all these sites, specimens of sphalerite, pyrite, chalcopyrite, chalcocite, magnetite, and galena literally cover the ground. The black matrix of much of this dense ore is nearly pure, massive magnetite, many pieces of which exhibit an unusually intense, natural magnetism.

A geological feature of interest is the Kneeling Nun Tuff, which formed through accumulation and compaction of volcanic ash some 35 million years ago. This 400-foot-thick formation is named for a skyline feature on a ridge overlooking the Santa Rita pit that appears as a kneeling, nun-like figure praying before a massive altar. When the volcanic ash compacted and lithified, it formed vertical joints or columns, one of which separated from the main formation, the “altar,” and slid downhill to become the “nun.”

The “Kneeling Nun” is in continuous geological transition. In 1885, miners reported seeing a 30-foot section of it tumble. Further fragmentation occurred during an earthquake two years later.

The “Kneeling Nun” is surrounded by legends and superstitions. A recent legend attributes the geological fragmenting to the “nun” trembling in awe at the sight she sees below—the seemingly never-ending expansion of the Santa Rita pit.

The Kneeling Nun Tuff has also created another prominent, regional landmark—the otherworldly landscape of City of Rocks State Park. Located 20 miles southeast of Silver City just off U.S. Highway 180, this “city” consists of a large cluster of 40-foot-high columns of Kneeling Nun Tuff rising from the valley floor. The park’s Visitors Center has excellent displays explaining the geology and exhibits of local rocks and minerals.

More to See, More to Enjoy

In Silver City, interesting specimens of regional minerals and ores are displayed at the Royal Scepter Gems & Minerals rock shop (www.royalscepter.com). The Grant County Rolling Stones Gem & Mineral Society (www.rollingstonesgms.blogspot.com), headquartered in Silver City, meets monthly. The Society’s activities include field trips and bus tours to mining sites. The club’s annual gem-and-mineral show is slated for Aug. 31-Sept. 2, 2019 at the Grant County Veterans Memorial Conference Center.

Specimens of native copper from Santa Rita are still available from shops and dealers. Interestingly, Santa Rita was North America’s biggest source of native copper, and is second only to Michigan’s Keweenaw mines. Examples of Tyrone district turquoise from the Big Burro Mountains can still be found in museums and historic collections.

Silver City is located on U.S. Highway 180 in southwestern New Mexico. It is a one-hour drive from both Lordsburg and Deming to the south on Interstate 10, and a two hour drive from Interstate 25 to the east.

For further information visit www.visitsilvercity.org.

Author: Steve Voynick

A science writer, mineral collector, and former hard rock miner, he is also the author of many references including, “Colorado Rock Hounding” and “New Mexico Rockhounding.”

A science writer, mineral collector, and former hard rock miner, he is also the author of many references including, “Colorado Rock Hounding” and “New Mexico Rockhounding.”