Story by Bob Jones

The Canadian Shield is the original heart, or core, of the North American continent. The rocks date to the earliest millennia of the planet.

Today, scores of mines operate in and around the Shield, extracting a vast variety of useful metals and minerals. The region has given up everything from gold to silver, nickel and diamond and shows no signs of running out of useful minerals.

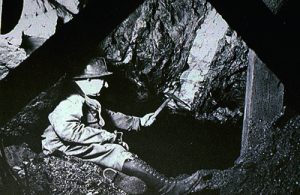

This was not always the case; just over 100 years ago, little mining was going on for a number of reasons. The area was vast, remote and inhospitable. Heavy snows and bitter cold during the long winters, and wild animals, voracious mosquitoes, and black flies during the warm months discouraged all but the brave or foolhardy. Even in the 1970s, when I ventured 100 miles north of Montreal in early June in search of fluorescent minerals, I found myself in the midst of the black fly season. I itched for the rest of that summer. Imagine what it must have been like prospecting the region in the 1800s!

Silver Changes the Scope

Then in 1903, something happened that changed mining and prospecting in the Canadian Shield forever. Silver was accidentally discovered 300 miles north of Toronto. In a few short years, massive silver production—exceeded only by that of Mexico and the United States—financed the search for and discovery of countless valuable mineral deposits across northern Canada, where mining is still ongoing today. How did all this happen?

The government was building a railroad some 300 miles north of Toronto in order to open up agriculture areas. The railroad passed close to Lake Kamiskaming and Long Lake. A venture like building a railroad requires a large support system, including people to cut timber for the ties and blacksmiths to produce spikes and repair equipment. I mention these two tasks specifically because they led to the great silver discoveries of the area.

It was in August 1903 that two woodsmen, James McKinley and Ernest Darraugh, were cutting timber for railroad ties around the edge of Long Lake. One of them noticed some odd-looking rocks on the edge of the lake. One piece he picked up proved to be a small sheet of metal. Knowing it had potential, the two cutters gathered a few odd-looking rocks and had them assayed. These lakeside rocks proved to be so rich in silver they assayed at $4,000 to the ton!

Darraugh and McKinley immediately filed claims and established a property they called the JBJ mine. What they had stumbled upon was just one vein that proved to be a small part of one of the world’s great treasure troves.

A few weeks after the McKinley-Darraugh find, railroad blacksmith Alfred La Rose was working at his trade in the area when a curious fox kept bothering him by sneaking around his workings. Annoyed, Fred threw his blacksmith’s hammer at the beast, but missed, hitting a nearby rock instead. As the story goes, the hammer chipped the rock, revealing a streak of metallic material in the interior.

Woodcutters and Blacksmiths Role in Early Mining

La Rose thought he had found a deposit of chalcopyrite, a common copper ore, because the chip had a coppery color. What he had was a piece of niccolite which, when tarnished, does look like chalcopyrite. La Rose showed his rock to a local expert, who pronounced it niccolite. But when the rock was tested, it proved to be very rich in silver. Immediately, Fred staked claims. It was the start of the La Rose mine, with ore that averaged around 1,500 ounces of silver to the ton!

The discoveries made by the woodcutters and blacksmith, who knew nothing about prospecting, became public knowledge when they filed their claims. People suddenly realized the wilderness area on the north side of Long Lake deserved serious prospecting, and the town of Cobalt was quickly established as the resulting rush drew people from all over. People who knew virtually nothing about prospecting stumbled onto riches beyond their wildest dreams.

Discoveries came thick and fast, and within eight years—between 1903 and 1911—over 31 million ounces of silver had been wrested from the rocks around Cobalt. And this was only the beginning. Silver mining, and later cobalt mining, continued into the 1960s.

Keep in mind that this area had been scoured by glaciers thousands of years earlier. The glaciers had scraped away the soil, exposing rock surfaces, including any silver veins that were locked in those rocks. One can only imagine how much silver wealth had been carried away by those glaciers. The glaciers left behind shallow depressions that later filled with snow melt and became lakes. The rocks and their valuable silver veins were slowly covered by soil, rotting vegetation, fallen timber, and the like. These were the conditions prospectors found when they arrived in the 1900s.

There were few exposed surfaces, so the prospectors had to dig into the ground cover to expose the rock in hopes of finding wealth. Trenching had to be employed in hopes of finding a silver vein. This method was quickly adopted as prospectors dug trenches parallel to each other about a few yards apart in hopes the top of a vein might be exposed. And it happened frequently. It was not necessary for newcomers to have any knowledge or experience in prospecting or mining to strike it rich. They simply had to get lucky!

Thick Veins of Silver

One fellow, William Trethewey, arrived in 1904, just a year after the first discoveries of silver. On his second day there, Trethewey found a rich silver vein! He named the mine after himself. Not satisfied, he continued prospecting the nearby area, and within a week he found yet another vein. This second find was exceptionally rich and became the Coniagas mine, which proved to be one of the richest veins ever found. When he opened this vein, he began shipping slabs of silver, which he simply peeled off the walls of the vein he was working.

These slabs were described as being as big as “boards from a barn”.

The silver in the Cobalt area occurred in thick veins, some of which were virtually solid metal. In one instance, miners following a vein of solid silver underground realized that it was widening. It become so thick and broad they knew it would be virtually impossible to mine. After all, silver is a malleable metal and does not break or shatter like a rock.

They realized a direct attack on the silver would be useless, so they decided

instead to try to expose it by blasting away the enclosing rock. Thus, they removed all the rock on either side of thick silver mass. They were left with a solid mass of silver metal about 6 feet long and a foot or more wide simply hanging from the ceiling of the tunnel.

Still, they had the problem of dealing with a very malleable metal. What to do? They devised a rather novel method to eventually crack and break the mass. Knowing that bending a piece of metal enough times will crack and break it, they decided to do just that. By placing a small explosive charge on one side of the silver and detonating it, they bent the silver off to one side.

They set off another explosion on the opposite side of the silver, bending it back in the other direction. They repeated this process until the “bending” finally broke the silver piece off. Then they were able to break it into small enough pieces to make it possible to haul it to the surface. Imagine a vein of nearly pure silver that big! Large, solid masses of silver were not a rarity here.

Discovery of the “Silver Sidewalk”

Some silver veins produced thousands of ounces of silver per ton! One vein that had been exposed by ancient glaciers was 27 inches wide and was exposed at the surface. This was originally discovered in 1904 at the La Rose mine, in the area between Lake Giroux and Kerr Lake, by surface trenching. The vein was originally named the Lawson vein, but as miners realized what they had it acquired a new name!

The exposed, solid vein ran well over 300 feet along the surface. The surface of the exposed silver was so smooth the vein came to be called the “Silver Sidewalk”! Can you imagine actually walking on a vein of pure silver? For a time, the silver sidewalk was a novelty in Cobalt while some legal matters were handled. In 1908, miners began to mine this immense silver vein, during which time they were able to establish its actual size.

The vein actually ran for about 350 feet on the surface and averaged about 18 inches in width. It extended down into the earth nearly 100 feet. This suggests the glaciers had removed an unknown amount of the vein that had been above its current position.

Once the size of the Silver Sidewalk was known and pieces of it were assayed, its total silver content was estimated at 10,000 tons of silver! When the La Rose mine was in its heyday, it was paying $1,000 a day when silver was selling for under a buck an ounce!

Reports say that two large pieces of the Silver Sidewalk were saved and donated to the Canadian government. One of these pieces weighed 1,640 pounds and was estimated to hold 9,715 ounces of silver. This section of the Silver Sidewalk was placed in the Royal Museum, located in the Parliament building in Toronto. Oddly, a few years ago I was told the piece had “gone missing”, though how a rock weighing over 1,600 pounds could go missing seems to be a bit of a mystery. Perhaps the rumor I heard was wrong or the piece had simply been moved from its original place in the building. Maybe someone in that area can confirm that!

Influenced by Superheated Hydrothermal Solutions

One has to wonder how such rich silver veins formed in the first place. The age of the deposit is Precambrian, well over 500 million years old. Some of the rocks are even classified as Archean, among the oldest rocks exposed in the earth’s crust. The later-forming silver veins were brought into existing cracks and faults by superheated hydrothermal solutions from deep in the earth. These solutions followed the faults and cracks toward the surface until they cooled and dropped their rich loads. Some of the cracks were narrower and ran parallel to the larger faults solid rock.

Along with silver, the solutions also brought in the native element cobalt and several nickel minerals, including niccolite and skudderudite, originally identified as smaltite. It is important to remember that, as the miners worked away from the main silver veins, the silver content of the rock dropped off. Miners encountered cobalt ore, as well. The low-grade silver and cobalt was tossed aside in the frenzy to mine only the high-grade silver from the main veins. In later years, the dumps, rich in both silver and cobalt, were worked over successfully.

metal. Pubic Archives, Ontario

There are two major faults in the Cobalt area that held the vast bulk of the metals, and along which most mines were located. The most important fault was the Cobalt fault, which produced over half of all the silver mined here. Thick veins of nearly pure silver assaying at several thousand ounces to the ton were not uncommon!

The other major fault was the Valley fault. It should be noted that the major faults actually extended under Long Lake, later named Cobalt Lake. The Canadian government owned the lake area, but eventually sold off the mining rights for millions of dollars. The lake was drained to get at the silver veins. Draining the lake caused a temporary, stinky situation, as thousands of fish died and their remains rotted. The local birds, however, cleaned up the carcasses.

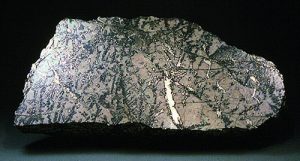

The host rocks invaded by the Precambrian solutions are diabase and greenstone. Diabase is a common volcanic rock similar to basalt. Greenstone is an ancient metamorphosed mafic rock, rich in iron and dark minerals like manganese. Many of the silver specimens I’ve seen from this area show the metal locked in masses of dark, quite ugly rocks. These specimens are not particularly attractive, but you hardly notice the matrix because of the beautiful silver sheets and masses jutting out of the matrix.

The more attractive Cobalt silver specimens occur with snow-white calcite as the matrix. The most beautiful are the wire silvers that were found locked in white calcite. Etching away the calcite exposes the graceful silver wires.

The metallic load mined from these veins contained far more than just silver. Millions of pounds of other metals have come from the Cobalt mines. This includes significant amounts of bismuth, arsenic, mercury and gold. The amount of gold recovered from the Cobalt area is estimated to exceed the amount mined in the Yukon during the huge rush there. More important than the metals mentioned are some 16 million pounds of nickel and an amazing 45 million pounds of cobalt.

As impressive as these amounts are, they are eclipsed by the astounding quantity of silver mined.

Silver Etched From Calcite Veins

Exceptional silver and other specimens from here are severely limited. Most of the silver was massive, sheet and chunks. One old government reports tells of chunks of silver like cannonballs being found on the ground. The nicest Cobalt wire silvers I’ve seen were all etched from calcite veins.

You would expect a silver deposit to produce quantities of silver sulfides and sulfosalts. Cobalt did yield limited amounts of argentite, acanthite, proustite and pyrargyrite, but you just don’t see specimens around today. In the early days of mining, the effort to retrieve native silver was so frenzied that anything that didn’t shine was bypassed or ignored.

By the 1960s, when mining at Cobalt tailed off dramatically, 420.5 million ounces of silver had been mined there. Keep in mind that, during the early days of mining here, ore that was low-grade was judged insignificant and tossed on the dumps. Before the mines finally shut down, the overall estimate of production is thought to be about 600 million ounces of silver.

As important as the silver wealth of Cobalt was at the time, it has proved to be far more important as the start of Canada’s hardrock mining efforts, mineral exploration, and the development of the vast wealth of the Canadian Shield.

Author: Bob Jones

Holds the Carnegie Mineralogical Award, is a member of the Rockhound Hall of Fame, and has been writing for Rock & Gem since its inception. He lectures about minerals, and has written several books and video scripts.

Holds the Carnegie Mineralogical Award, is a member of the Rockhound Hall of Fame, and has been writing for Rock & Gem since its inception. He lectures about minerals, and has written several books and video scripts.