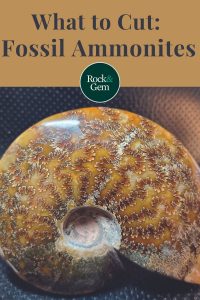

Fossil ammonites are highly sought after by fossils collectors and by lapidaries for jewelry designs. The colorful iridescent display catches the eye.

Varieties of Fossil Ammonites

Smaller-sized fossil ammonites are often used to carve out the inner cells to inlay stone material. The larger size fossils are cut to form cabochons.

The Cleoniceras Ammonites from the north side of Madagascar are the most sought after for their size and beautiful root beer iridescent colors with intertwining fern leaf patterns. The golden-brown coloring is from the fossilization of 120 million years of water mineralization replacing the shell with calcite. This material is on the soft side, but still stable enough to work.

Purchasing Considerations

There are several factors to consider when searching for materials to purchase:

• If you have not seen a whole ammonite in person, know that both sides are uneven. Spirals on the inside are tighter and thinner than at the opening of the shell.

• A fossil ammonite is entirely curved with no flat surfaces. This can create a challenge in the cabbing process.

• A fossil ammonite is entirely curved with no flat surfaces. This can create a challenge in the cabbing process.

• Look carefully at both sides of the ammonite to see how much working area you will have since you will be cutting it in half to use both sides for cabochons.

• Gray patches are usually porous, crumbly and unusable, so focus on the areas with color.

• Hollowed cells inside can mean you don’t have enough material to cut cabs unless the cells are filled or backed.

Getting Started

First, cut the entire ammonite in half creating two identical portions to use. Then examine the inside to see if it needs to be filled with epoxy or backed for stability.

First, cut the entire ammonite in half creating two identical portions to use. Then examine the inside to see if it needs to be filled with epoxy or backed for stability.

Once you have the two sides cut and prepared, you are ready to draw out your design. Carefully choose areas that can be cabbed that don’t have a great deal of an arch across the top or an uneven area that will have to be ground down to an equal height causing you to lose the top coloring on a portion of your cab. Remember that the outer layer is much darker, iridescent and thin.

Because it’s comprised of calcite, it’s easy to grind through the top layer and lose that lush darker color. It will sand down too far yielding a light golden yellow and the pattern may be lost. To make sure this doesn’t happen, cut your preforms to the shapes you desire, and grind the backside flat as you attempt to make an even girdle height around the sides.

Cabbing Fossil Ammonites

It’s best not to use heavy coarse grit wheels and go right to the 280 soft resin wheel to gently dome the top of your cab and finish shaping it. There’s not much you need to do, since the 280 will grind this soft material rapidly. Do only the bare minimum at this stage!

Once you have it shaped and domed, allow the 600 grit wheel to remove any remaining scratches. Be sure to dry your cab off thoroughly and check for scratches and to see if you are removing too much of the top layer.

Now you can move forward to the 1200 grit stage, continuing to use a gentle touch. Even the 1200 grit can remove material when it’s this soft. To finish, use a 14k grit soft resin wheel. It should bring your piece to a beautiful gloss finish with no need to go any further.

Now you can move forward to the 1200 grit stage, continuing to use a gentle touch. Even the 1200 grit can remove material when it’s this soft. To finish, use a 14k grit soft resin wheel. It should bring your piece to a beautiful gloss finish with no need to go any further.

If you desire to attempt a mirror glossy finish, you can use Zam polishing compound and a polishing tip on a Dremel. Do only the bare minimum so you don’t overheat and crack your cab.

This What to Cut column about fossil ammonites previously appeared in Rock & Gem magazine. Click here to subscribe! Story and photos by Russ Kaniuth.